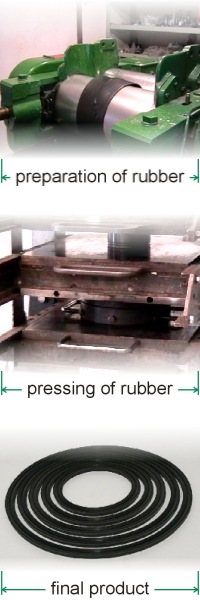

Material

Rubber, polyurethane

Mainly technical moulding forms the basis of the used material, and it has a different quality according to the specific requirements of customers and the demands of the environment, where the products work. A wide scale of commonly accessible rubber stock, for example: EPDM, NBR etc. are used, but as well polyutherane, which is qualitatively on an upper level.

Features

During the production, compounds with hardness from 35 do 95 Sho are used and with solidness from 2,5 to 21 Mpa, and they are in colour shemes according to the requirement of customers. The choice of the suitable material depends on the operating instructions, in which the products work. The most commonly used compounds are heat resistant, oil resistant, resistant against mechanical and dynamical straining.

Quality

REO endevours to provide its customers the production of the highest possible quality, for that reason it cooperates with the distributors of material, who are possessors of ISO 9001 certificate, and the quality of each delivery is checked and is provided with a test certificate.